contacts:Mr. xiong

phone:18665576061

Tel:18665576061

Add:No.35 huangcun Rd,Tianhe District,Guangzhou china

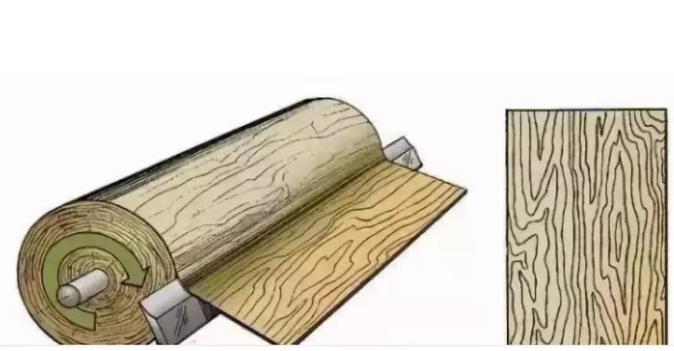

In the production of Engineered veneer, the length of wood segments used for rotary cutting veneer is generally 1900mm, 2300mm, 2600mm, 2900mm, and 3300mm. The production of boards is similar, but special attention should be paid to the following points:

1、When rotary cutting, non porous adhesive tape is usually used to seal the ends of the veneer at both ends to prevent damage to the veneer. The spacing between the sealing ends should ensure that it meets the minimum length required for technology wood production, so as not to affect the dyeing (or bleaching) effect of the subsequent process. Generally, the end sealing adhesive tape must be controlled within 50mm of both ends. Current Department

The end of the veneer used in the sub technology wood veneer variety does not need to be sealed with adhesive tape, in order to prevent the adhesive tape from falling off during the bleaching and dyeing process. After drying, it is firmly adhered to the veneer, affecting the bonding strength and damaging the design texture pattern.

2、 When rotary cutting, it is necessary to ensure the sharpness of the rotary blade and avoid blade gaps to ensure that the surface of the veneer is smooth and conducive to bonding.

3、 The thickness of the rotary cut veneer should be uniform and consistent, and the thickness deviation should be controlled within ± 0.02mm. Single board rotary cutting equipment includes single card axis, double card axis, and non card axis rotary cutting machines. At present, the rotary cutting of logs adopts dual card shaft and non card shaft rotary cutting machines. The rotary cutting machine with double cardan shaft and pressure roller device starts to rotate and cut large

When using diameter grade wood segments, the inner and outer clamps on both sides of the left and right simultaneously block the wood segments to maintain sufficient torque to ensure normal rotation and cutting. When the diameter of the wooden section decreases to a slightly larger diameter than the outer clamp head, hydraulic transmission is used to withdraw the outer clamp heads on the left and right sides from the wooden section to the main clamp heads on the left and right sidesOutside the slider (i.e. semi circular slider); The inner clamp head (i.e. small diameter clamp head) continues to clamp the wooden section for rotary cutting, as shown in the figure.

In order to avoid bending deformation of the wood section due to the force of the rotary knife, pressure gauge, and clamping shaft, when the diameter is reduced to about 125mm (depending on the tree species, length, etc. of the wood section), the pressure roller can automatically press on the top of the wood section and relative to the other side of the rotary knife, press on the wood section to prevent deformation.

The wooden segment undergoes bending deformation in the direction of upward and away from the rotary blade. This allows the wood core to be directly rotated to 65mm on the same rotary cutting machine. The pressure roller can also adopt power transmission, which not only prevents bending deformation of the wood section during rotary cutting, but also assists in the rotation of the wood section, effectively reducing the diameter of the wood core

Long pressure rollers should be used instead of short pressure rollers. During rotary cutting, the position of the clamp head after penetrating into the wood segment does not change and remains twisted to a certain extent,

But axial pressure can be reduced. This requirement cannot be achieved by mechanical advance and retreat of the shaft, only hydraulic transmission can achieve it. Based on the above analysis, the traditional rotary cutting machine currently used relies on a clamp shaft to support and rotate the wood segment. This method has its shortcomings, namely rotary cutting

There will always be wooden cores left behind, which cannot be fully peeled into single boards. Therefore, a non card shaft rotary cutting machine can be used. The support and rotation of the wooden section are provided by the support power roller, and the upper pressure roller serves as a positioning and pressure gauge. During rotary cutting, the rotary knife is fixed and the upper pressing roller is also fixed and only supports movement

The force roller rotates synchronously and moves upwards to ensure that the wooden segment is always under the pressure roller, ensuring continuous rotation of the veneer. The upper pressing roller can move up and down, adjusting the distance between it and the rotary knife. The size of this distance determines the thickness of the veneer.

Using this type of rotary cutting